Pallet Storage Forklift Rail Guided Aisle Tunnel Drive In Rack

Basic Info

Model No.: JRDIT-DX/TD/EU

Product Description

Pallet Storage Forklift Rail Guided Aisle Tunnel Drive In Rack

Drive in / through rack system is ideal for stocking large quantities of relatively few product types. It can reduce overall square footage requirements by 35 - 60 percent compared to the conventional Pallet Rack configuration. Drive in / through rack system can be applied in cold storage Warehouse. It is widely used in food, drink and tobacco industries.

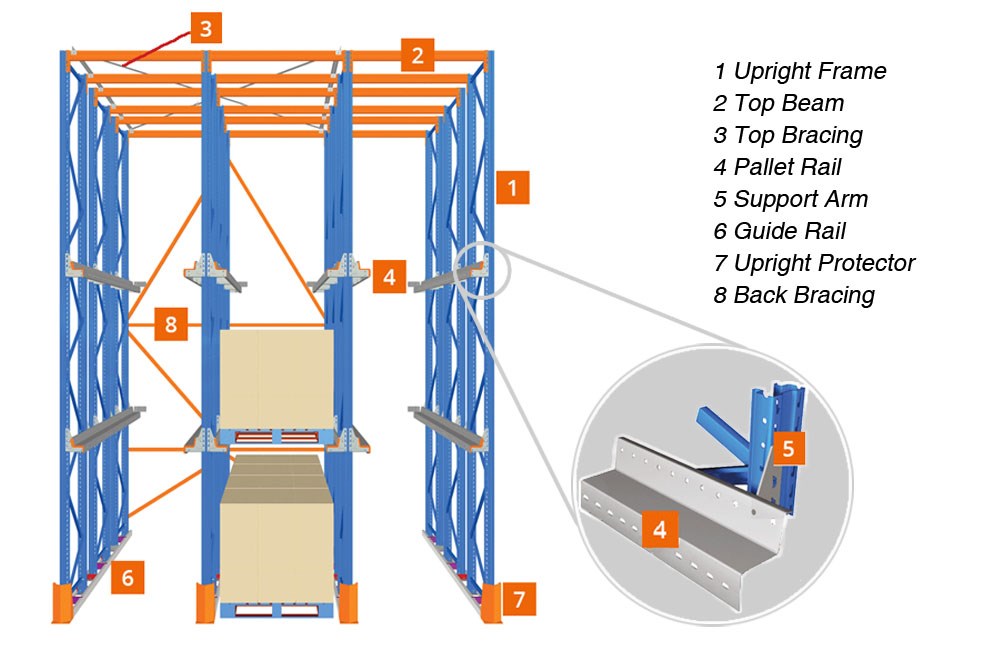

Drive In / Through Rack Structure

Advantages of JRACKING® Drive In / Through Rack

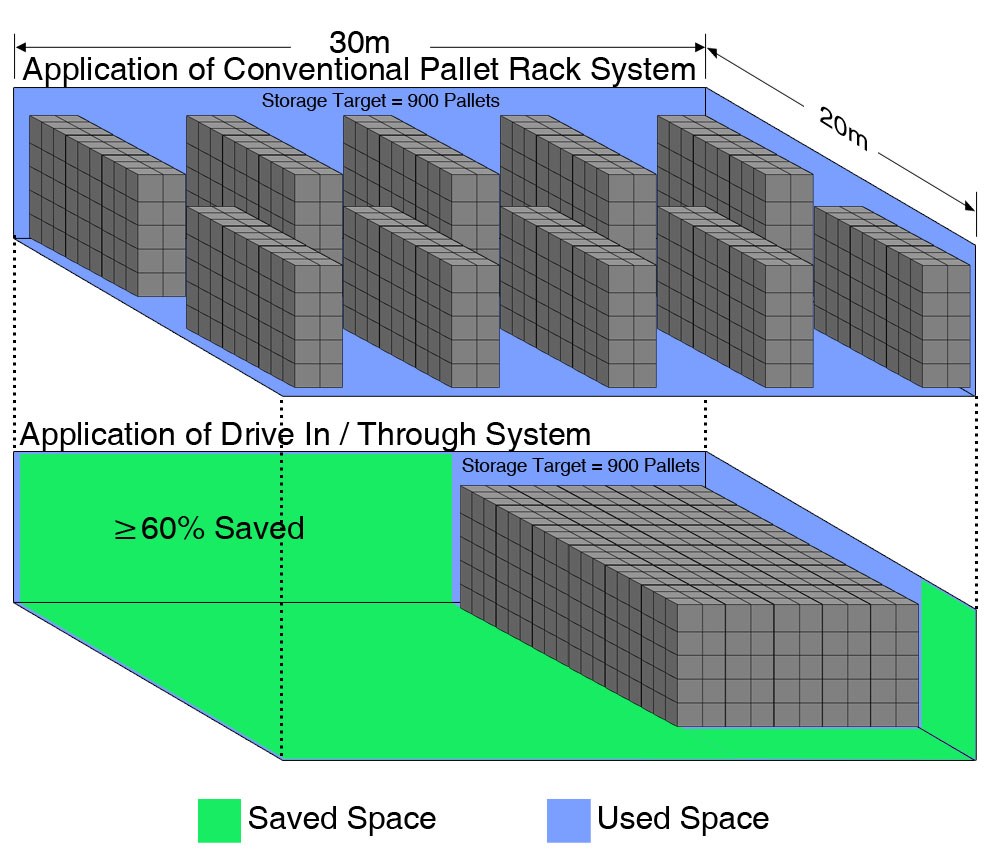

Warehouse Space Saver

All racks integrated as one complete structure to minimize the waste using of spaces.

E.g. 900 Pallets storage space comparison (shown as image)

Conventional pallet rack:

Whole warehouse 30x20 sq.m.

Drive in / through rack system:

Only 40% of the space 14x18 sq.m.

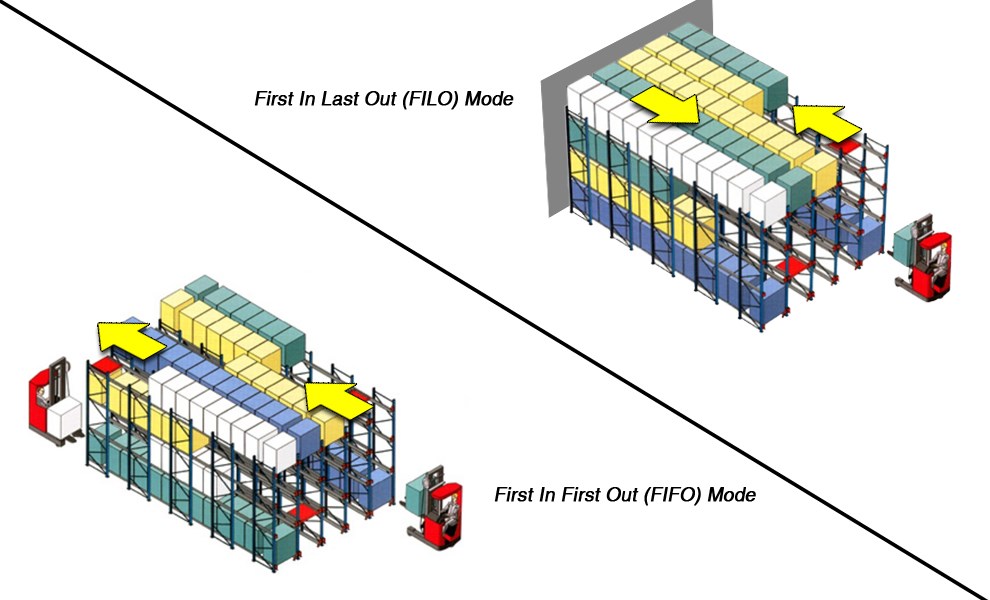

Massive Storage & Pick-up

The drive in / througth racks are the highly integrated system which is very suitable for massive storage and pick-up. For different warehousing management purposes, the system could be settled by First-In-Last-Out (FILO) mode or First-In-First-Out (FIFO) mode. FILO mode is suitable for the goods with long-term or no expiration warranty, such as electrical products, clothes and shoes, office supplies, tobacco etc., and the FIFO mode is usually applied for short-time validation products with pack-to-deliver purpose in manufacture warehousing facilities, such as pharmaceutical products, food and drinks etc.

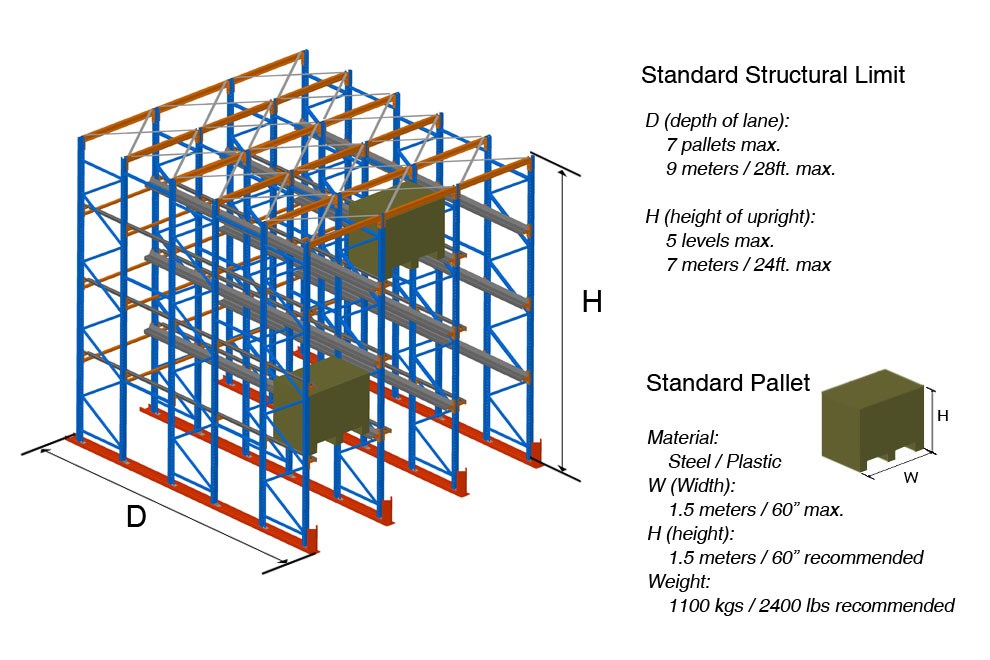

Type selection of drive-in system

Warehouse Circumstances & Storage Objective

The size of the warehouse decides the rack layout including 1) the length, width and height of the warehouse, and 2) the locations of the doors and gates, pillars, power boxes, firefighting facilities etc.

Storage objective also affect the choosing and layout of racking system. Considering the safety factor of the drive in / through rack system, the total height should not exceed 5 levels (usually 7 meters / 24ft.), and depth of the lane should not exceed 7 storage space units (usually 9 meters / 28 ft.), and pallet weight should not exceed 1100 kgs (2400 lbs).

Forklift Dimension

The width, maximum elevation height and the turning radius all affect the rack selection and layout.

Certificates

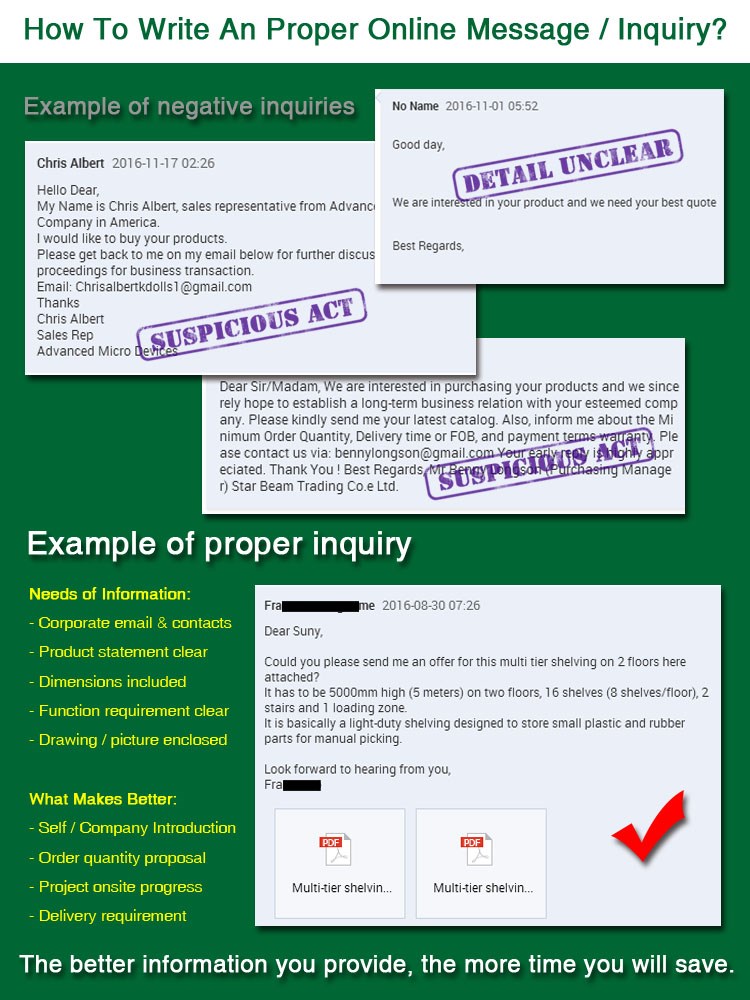

Q: What’s your trading terms?

1) Payment terms: T/T 30% deposit after order confirmed, 70% balance paid against bill of lading. L/C O/A also available.

2) Lead time: normally in 20-25 days after deposit received.

3) Sample policy: samples are always available for each model. Samples can be ready in 7-15 days once payment received.

4) Shipping port: Shanghai / Nanjing China.

5) Discounts: we offer good discount for large quantity.

Q: How I can delivery my goods?

1) Sea freight: we will update sea freight once we know your sea port where goods will be delivered.

2) Agent designated by client: please tell us the contact detail of your shipping agent and we will arrange to deliver the items.

Q: What is your service?

1) Your inquiry related to our products or price will be replied in 12 hours.

2) Well-trained and experienced staffs to answer all your inquiries in fluent English.

3) OEM & ODM, any your customized racking we can help you to design product.

4) We have very experienced professional engineers to make best solutions.

Q: What's the international trading process?

Design drawing → Confirm drawing → Quotation → PI → Confirm PI → Arrange 30% deposit → Manufacture → QC inspect → Pay balance → Shipping

Q: What’s your advantage?

1) Payment: we can do O/A 40-60 days.

2) Lead time: rush order we can fast delivery.

3) Factory price: factory direct sale competitive price.

4) Warranty: Two years warranty, the broken parts will be replaced and sent to you.

Q: Does Jracking® have MOQ (minimum order quantity) limitation?

A: No, but good quantity comes with good price. We recommend the order quantity for regular products of Jracking® to fit at least one 20ft. container, which is about 15 tons.

Q: How does Jracking® charge tooling fee (cost of opening new mold)?

A: For the production of necessary tooling requirement, Jracking® charges the cost before the first order for opening new mold, and the cost will be partially or fully refunded after certain quantity of orders.

Product Categories : Special Purpose Racking > Drive In Racking

Premium Related Products