chemical storage equipment,Nanjing Jracking sheet metal storage Q235 steel used pallet racking

Basic Info

Model No.: Drive in storage rack

Product Description

Nanjing Jracking sheet metal storage Q235 steel used Pallet Racking :

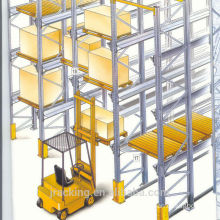

Drive-in & through rack Advantages:

1. Suitable for small variety but large quantity stored products, especially for standard goods;

2. Very high utility ratio of the Warehouse;

3. Each aisle consists of several level of pallet support rail. Pallets are placed on pallet support rail one after another;

4. Forklifts operation alongside the aisle;

5. First-in-last-out access process, one side in/out or two side in/out can be met.

6. Top and back bracing are used to fix the whole racking, making the whole racking stable and safe;

7. First level pallets can be placed on the floor;

8. Surface treatment: powder painting;

9. Different size available

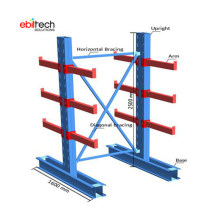

Load Rails are constructed of durable structural angle steel, providing increased strength and abuse resistance. Standard features include:

1. Structural angle rails "guide" pallets, ease of use and durability

2. Flared rail entry ends allow easy bay access

3. Space-saver low profile arms increase clearance and decrease possible product damage

4. Welded rail stops prevent loads from being pushed off, improving safety

5.75mm vertical adjustability

6. Welded aisle-load arms to eliminate hazardous load projections into aisles

7. Grade 5 hardware

Drive-In & Drive-Through Racks offer the ability to store a large amount of similar loads in a smaller area. Selectivity is sacrificed, but storage density is outstanding. Drive In Racking can store up to 75% more pallets in the same space than selective racking -- depending on your application. It requires fewer aisles and is better cubic storage.

Metal heavy duty warehouse rack Features

- The most commonly used, of all storage systems for palletised goods. Low capital cost. Easy installation and simple to adjust.

- Compatible with most types of handling equipment.

- Less storage density compared to other pallet racking systems

Beam

- High load capacity up to 4200kg.

- Manufactured with the highest quality steel.

- Orange epoxy coated (RAL 2004).

- Lengths available: 1850/2250/2700/3300/3600/3900mm

- Boltless connection with 3 or 4 connector hooks.

- A security pins per beam to prevent accidental dislodgement.

- Powder Coating finish

Accessories

Packing and Loading

our two Factories

The old factory covers an area of 24000 square meters. With an area of 31000 square meters, the new factory is under construction and will be put into operation in August this year. The advanced automatic production facilities for the cold profiling of metals enable us to achieve high level in racking industry. Rigorous tests are implemented on raw materials, half finished and finished products, which ensure us a continuous evolution of efficiency and quality standards

Workflow

Send us your CAD drawing and we will give you a quick online quote, or you just tell us your tridimensional dimension of your warehouse we can design and draw drawings for you within 48 hours.

Competent Responsibility Demand Honour

Sincere thanks for scanning our products, and your satisfaction will be our greatest pleasure.

For a QUICK QUOTATION, please provide below information:

1. | Drawing (if available) |

2. | Size of your warehouse |

3. | Size of racking (H*W*L) |

4. | How levels of the racking? |

5. | Loading capacity of each level? |

6. | (RAL) Color you want. |

Product Categories : Special Purpose Racking > Drive In Racking

Premium Related Products