Holz Regalsystem Warehouse Push Back Pallet Rack System

Basic Info

Model No.: Holz Regalsystem Warehouse Pallet Push Back Rack System

Product Description

Holz Regalsystem Warehouse Push Back Pallet Rack System

Push Back Racking push-back Pallet racks push back shelves :

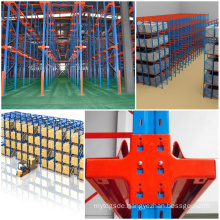

Standard Jracking Push Back Rack is an accumulative storage system that allows you to store up to four Pallets deep per level.

All of the pallets on each level, except the last, are placed on a set of trolleys that are pushed along the rolling rails. These rails are built on a slight incline, lower at the front, so that the pallets at the back move forward when the pallet closest to the aisle is removed.

All the pallets placed on a particular level must contain the same SKU and are managed using the Last In First Out (or LIFO) system.

Push back racking push-back pallet racks push back shelves Advantages:

1. A compact storage unit means that the best possible use is made of the space available, compared with conventional system.

2. Ideal for storing medium turnover products, with two or more pallets per SKU.

3. Very little height and space are wasted.

4. Unlike other compact system, each level can be used to store a different SKU.

5. The pallet centralisers, stops and blocking devices make loading and unloading operations safer and easier.

Push back racking push-back pallet racks push back shelves features:

- The most commonly used, of all storage systems for palletised goods. Low capital cost. Easy installation and simple to adjust.

- Compatible with most types of handling equipment.

- Less storage density compared to other Pallet Racking systems

Beam

- High load capacity up to 4200kg.

- Manufactured with the highest quality steel.

- Orange epoxy coated (RAL 2004).

- Lengths available: 1850/2250/2700/3300/3600/3900mm

- Boltless connection with 3 or 4 connector hooks.

- A security pins per beam to prevent accidental dislodgement.

- Powder Coating finish

Frame

- High load capacity up to 21000kg.

- Frames include all the elements needed for assembly: bracing, feet and nuts & bolts

- Blue epoxy coated (RAL 5017).

- Standard heights : From 2 -11.5m

- Adjusted by 50mm pitch.

Beam and Upright

Accessories

Packing and loading

Our Two Factory

The old factory covers an area of 24000 square meters. With an area of 31000 square meters, the new factory is under construction and will be put into operation in August this year. The advanced automatic production facilities for the cold profiling of metals enable us to achieve high level in racking industry. Rigorous tests are implemented on raw materials, half finished and finished products, which ensure us a continuous evolution of efficiency and quality standards.

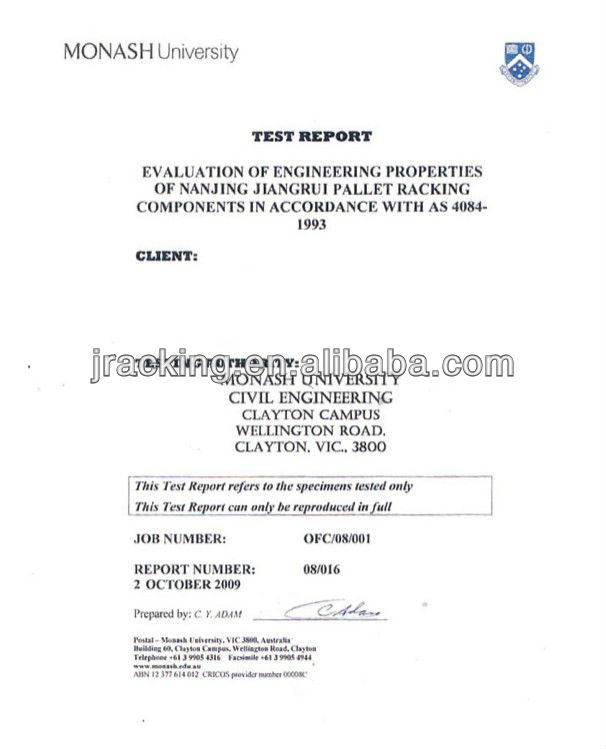

Certifications

Our company ISO 9001:2000 quality assurance system is certified by SGS. All ensure high quality standards according to the international famous certification bodies, such as the European Racking Code FEM 10.2.02. The British Storage Equipments Manufacturers Association (SEMA). The American Rack Manufacturers Institute Specification (RMI) and the Australian Standards --Steel Storage Racking AS4084--2012

Product Categories : Special Purpose Racking > Push Back Racking