Thin sheet leveling and cut to length machine

Product Description

Thin sheet leveling and cut to length machine

Features of cut to length machine:

1. The production line is a thin metal coil leveling and cut into a massive part of special equipment. Usually cited by the feeding car, uncoiler, Pallet pressure device, levelimg host activties across the bridage, guide corrective devices, length agencies, film equipment, shears, converyor table, pneumatic discharge rack, hydraullic life the composition of the pile material, maetrial transport roller and hydraulic system, electrical control system, the concerted action of PLC control. The main hydrallic, pneumatic and electronic control system, cut to lenght system, selected international brands.

2. This equipment is mainly used for processing cold-rolled carbon steel coil, stainless steel coil and non-ferrous metal coil, configuration, six leverler to the entire pacification of long shear plate surface of the metal alumnium and other high coil.

3.According to the customer requirements, the fine two leveler can be used eariler; fixed lenght sent to shear can be ordinary mechanical appliance collaborative action, digtial, variable frequency or AC servo technology.

Board thickness: 0.3-2, 0.5-3, 1.5-5mm

Board Width: 800, 10000, 1250, 1500, 2000

Uncoiler load bearing: 5, 12, 15 Ton

Leveler fiantness: 1mm

Cut to length working speed: 70, 80, 100m/min

Total power:65, 95, 110kw

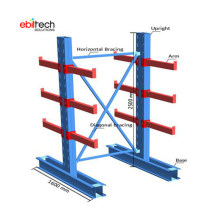

Thin sheet leveling and cut to length machine is composed by the following elements:

1.Loading car

2.decoiler

3.Fedding material equipment

4. Bridge of transition

5. rectify a deviation device

6.leveling machine

7. Length sizing machine

8.cutting machine

9.deliver platform

10.runout table

11.hydralic sation

12.PLC station

For the machine, we strictly obey to the rule of ISO9001 system in order to make sure the machine quality. We have more than 16 years in making this kind of cut to lenght machine with enough tech information and on-side pratical experience.

Take one of the simplest leveling and cut to lenth machine for example:

Material thickness:1.8

Material width:1250mm

Decoiler:

1. Hydraulic Coil inner diameter: 450-520mm

2 .Max coil width: Max coil width 1300mm

3. Carrying capacity:5000kg

4 .Hydraulic expansion

5 Automatically feeding

6 Hydraulic, inner tight

7 Hydraulic power:3 kw Drive power:3kw

8 Size:2.7*1.3*1.8m(L*W*H)

Main specification

1).Machine frame:350H steel welding

2).Material of forming mold:45# steel with quenching

3).outer diameter:φ90

4).Main motor power: 5.5kw

5).Speed:10-15m/min

6).Forming steps: Up layer: 5 steps Down layer: 6 steps

7).Transport way: Chian

8).Voltage:380v 50hz 3phase

Warranty

1. One year, and we will provide the technical support for the whole life.

2.Training: the buyer should charge of visa, return ticket, food and accommodation overseas and USD50/person/day for salary.

3. Need one technicians

4. Training time: one week (contains the time of installation and adjustment)

Product Categories : Slitting Line/Cut To Length Line