Jracking Selective storage rack workshop equipment

Basic Info

Model No.: Workshop equipment

Product Description

Jracking Selective storage rack workshop equipment

Nanjing Jiangrui Storage Equipment Co.,( 54296348,Jracking in short) Ltd. devotes itself to the design and manufacture of storage equipment. We are specialised in producing various Pallet Racking, longspan shelving, Cantilever Racks, rivet shelving, drive in racks, mezzanine and platform, canton flow rack, stacking racking and other related storage equipment.

Heavy duty Storage Racks workshop equipment Description:

Compatible Pallet Rack consists of upright frame, beam, Pallet support and other standard components.

H-bracing and D-bracing connect with upright part by self-lock bolts; can effectively prevent racking from losing balance caused by the release of bolts. The beam can be easily adjusted each 3” (76.2mm) on the upright to meet your variety loading height requirements.

Our pallet rack is easily utilized with just standard fork- and hand-trucks. Pallet racking is an ideal starting point for all your Warehouse and storage needs.

Features

1) Fully compatible and inter-chargeable with original Jracking MK6 pallet racking

2) Widest range of sizes available

3) Tough powder-coat finish resists rust and scratches.

4) Manufactured to meet the European standard FEM 10.2.02. And have been tested to comply to Australian standard AS 4084-1993.

Workshop equipment Advantages:

Versatility and flexibility to meet any storage needs:

1. Heights from 1800 mm to 5000 mm

2. Frame widths from 400 mm to 1500 mm

3. Shelf loading capacity from 250 to 600 Kg per level

4. Maximum load per bay up to 5000 Kg

5. Uprights available inΦ1.5 to 2.0 mm steel

6. Choice of steel or timber shelves (for steel, powder-coating or zinc)

Name | Compatible Pallet Rack for Warehouse Storage |

Model | DX-5 |

Approval | ISO9001:2008,CE,AS4084 |

Material | Steel Q235B |

Surface | Powder coated/Hot dip galvanised |

Quality Warranty | 3 Years |

Loading Chart of frame:

Size(mm) | Steel thickness(mm) | Frame loading(kgs) |

85x70(Standard Duty) | 1.8 | 8,000 |

2.0 | 10,000 | |

2.3 | 12,000 | |

100x70(Heavy Duty) | 2.0 | 12,000 |

2.3 | 14,000 | |

2.5 | 16,000 | |

120x95(Extra Heavy Duty) | 2.5 | 18,000 |

2.75 | 21,000 |

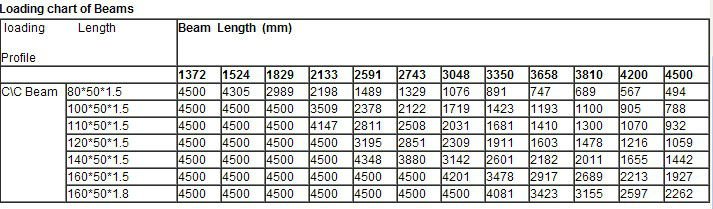

Loading chart of beams

Standard pallet racking is so far the most versatile one of any racking as it is available with many configurations, a wide range of accessories which make the racking more safe and stable.

Don't know how to organise your storage?Need help and advice designing your new warehouse layout?Contact us for help and advice by mail.

How to Select Pallet Rack

1. Frame Capacity

Add total weight of all Pallets for each bay (exclude pallets on floor).

2. Height

Measure all verticals including height of pallet, pallet load and beam height, add at least 100mm clearance between top of load and bottom of beam above. Top beam should be a minimum of 160mm less than maximum lifting height of your Forklift.

3. Depth

Pallet should overhang frame by 50-100mm front and back (1200 pallet, use 1100-100mm deep frame). Deduct 100-200mm from pallet depth. Pallets need to be in good condition.

4. Width

Measure width of pallet, add a minimum of 75mm pallet-to-frame clearance and 100mm between pallets to determine correct beam length. Each pair of beams must support weight of pallets per level. Add-on sections require only one additional frame and

required number of beams.

workshop equipment shows

VAN racking

Longspan pallet racking

Workshop equipment Accessories

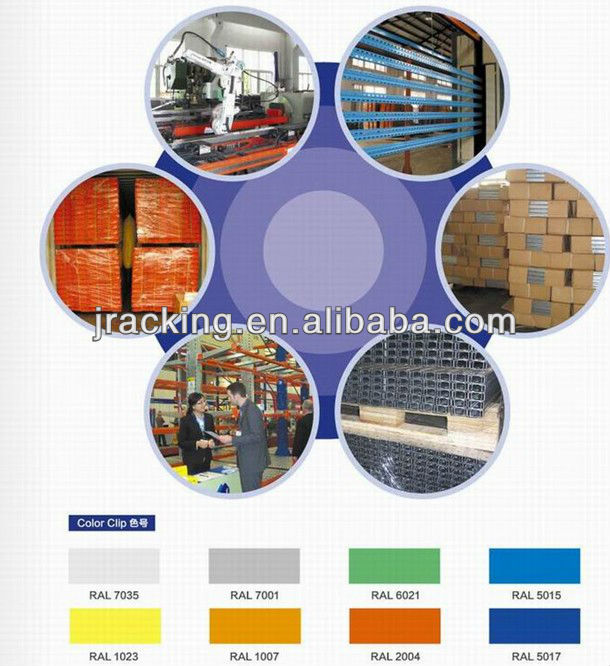

Process and Color Clip

Workshop equipment Packing and Loading

Our Two Factories

The old factory covers an area of 24000 square meters. With an area of 31000 square meters, the new factory is under construction and will be put into operation in August this year. The advanced automatic production facilities for the cold profiling of metals enable us to achieve high level in racking industry. Rigorous tests are implemented on raw materials, half finished and finished products, which ensure us a continuous evolution of efficiency and quality standards.

Certifications

Our company ISO 9001:2000 quality assurance system is certified by SGS. All ensure high quality standards according to the international famous certification bodies, such as the European Racking Code FEM 10.2.02. The British Storage Equipments Manufacturers Association (SEMA). The American Rack Manufacturers Institute Specification (RMI) and the Australian Standards --Steel Storage Racking AS4084--1993.

Product Categories : Ungrouped